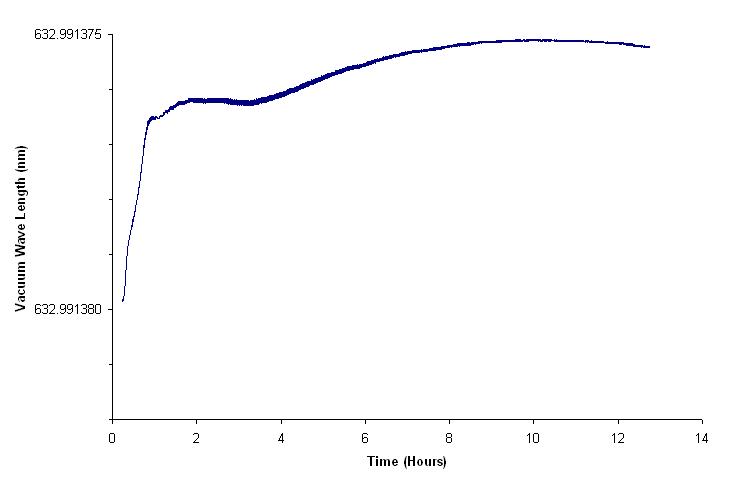

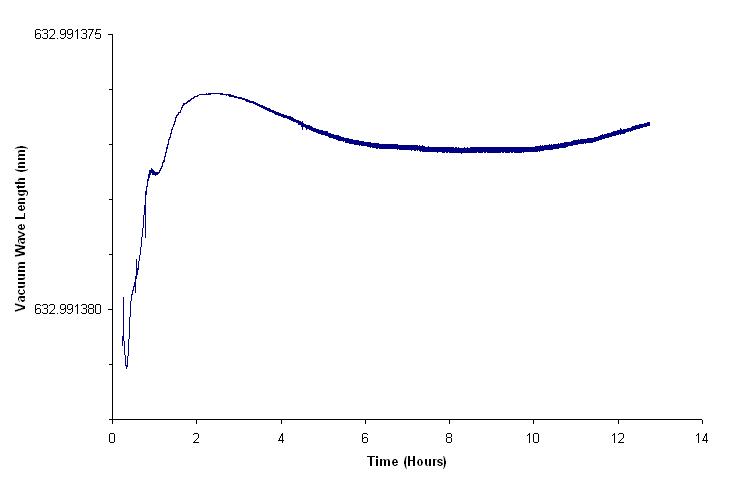

With laser interferometry, it is vital that the tuned wavelength of light is stable as

this is the base reference for all measurements. The Keysight

laser interferometry system is built around an in house designed and

manufactured Helium Neon laser source of great stability and long operational

life (50,000 hours). A testament to the stability of the laser head can be seen

from the results of wavelength checks in December 2001 (Figure 1) and December

2004 (Figure 2).

This shows a 9 year old Agilent long range (80m) laser head, regularly used for machine tool

calibration, which has been regularly calibrated by the NPL (National Physical

Laboratory, Teddington, UK). Each

calibration shows measurements of wavelength of light of the laser after switch on from

cold over a period of 12 hours. The mean vacuum wavelength for this laser tube

was reported as 632.991376 nm in December 2001 and 632.991377nm in December

2004, a change of 1 femtometre on the basic wavelength or 0.0016µm/m.

While this is the basis for an excellent laser calibration system, other factors

have far more influence on the final accuracy of a complete laser system. These

include, but are not limited to, sensor errors, optical alignment and

calibration uncertainties.

Figure 1 – Variation of laser wavelength with time. December 2001

Figure 2 – Variation of laser wavelength with time. December 2004

Back to Keysight Lasers or Calsure Calibration Software

C. D. Measurements Ltd., Chomlea House, Hadfield Road, Hadfield, Glossop, SK13 2ER, U.K.

Tel. 01457 852929

Email : sales@cdmeasurements.com

All Trade Marks Acknowledged